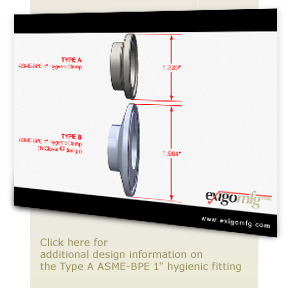

Type A ASME-BPE Standard

1” Hygienic Clamp Fitting

All hygienic clamp-fitting designs in use in the U.S. today originated with a Ladish/TriClover™ patent dating back many years. Since that patent ran out, there have been many applications developed for this fitting design and it is seen in every sanitary installation throughout the world. Over the years, dimensional variations from the many sources of these fittings have caused tremendous problems in the sanitary/pharmaceutical manufacturing community. Recognizing the severity of this problem, in 2005 the ASME-BPE Standard was revised to formally organize standardized dimensions for these fittings.

After solving the standardization problem, ASME-BPE turned its attention to solving issues with the 1” hygienic clamp fitting. Development work within the ASME-BPE community concluded that industry consensus about leakage, gasket deterioration and product contamination pointed to a flawed design. As a result, the ASME-BPE Dimensions and Tolerances subcommittee has introduced a new, alternative 1” design hygienic clamp fitting that will be added to the 2009 version of the ASME-BPE Standard.

Benefits of the new design

- 79% smaller gasket-sealing surface area concentrates the sealing force and requires a significantly smaller amount of elastomer to seal.

- Sealing mechanism is a “controlled-compression” type. This makes the elastomeric seal compression more uniform and predictable — which addresses some of the problems of the former design.

- The overall fitting size is greatly reduced, resulting in significant cost reductions.

- The fitting is designed to utilize an existing clamp based on a German/European DIN (DIN 32676 sizes DN 10,15,20) Standard design so clamp products are currently available.

Challenges of the new design

- Confusion regarding nomenclature ...

Creating alternative standard designs requires additional nomenclature for ordering and use. There will be some confusion because, for the 1” size only, an additional specification parameter is required to differentiate between the old and new styles.

- Type A has been designated as the 2009 ASME-BPE Standard for all controlled compression type fittings, which will include fractional sizes.

- Type B is the designation for all free compression type fittings (1” and above).

- In order to provide consistency, ASME-BPE has assigned this parameter to all sizes, but currently only the 1” has both alternatives.

- Type A has been designated as the 2009 ASME-BPE Standard for all controlled compression type fittings, which will include fractional sizes.

- Community education will be required to minimize confusion and provide guidance.

- Adapter fittings to compensate for prohibitive replacement costs … Legacy installations have millions of Type B fittings in use. It will be cost prohibitive to replace them all with Type A for working installations. Therefore, Exigo Manufacturing has developed adapter designs for any possible fitting combination.